Pallet detection: Speed up picking processes with PDS

PDS (pallet detection system) is a software solution for faster, fully automatic detection of all standard pallet types with two pockets in six degrees of freedom. In combination with the O3D3xx hardware, pallet position detection is extremely fast without accuracy being impaired. This constitutes a reduction of the overall cycle time of pallet detection in autonomous and semi-autonomous pallet handling vehicles.

The pallet detection system directly improves the performance of autonomous and semi-autonomous vehicles by increasing the speed with which the pallet position is detected without accuracy being impaired.

Time saved per pick

| Without PDS | 5 sec | |

| PDS | 0.8 sec | |

| Δ time | 4.2 sec |

PDS used at Tecnoferrari

Increased efficiency with PDS

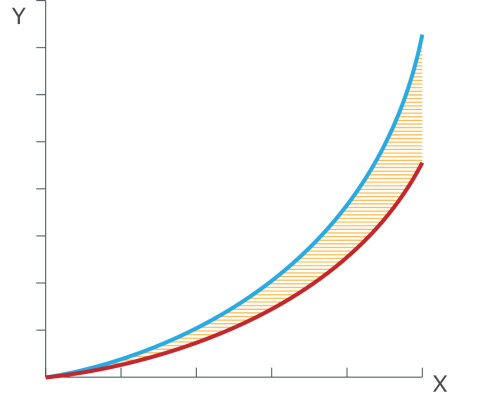

Data based on 12 picks per hour per vehicle

OEE (Overall Equipment Effectiveness) is the standard for measuring manufacturing productivity. Simply put, it indicates the percentage of the total production time that is truly productive.

|

|

|

|

For a robotics application, the most important indicator of the OEE is the performance rate, which indicates slow cycles and small stops. This value indicates how many percent of the maximum possible performance are achieved. That means: It indicates the efficiency of the application. With PDS, the performance rate – i.e. efficiency – is increased, as the time needed to pick up the pallet is reduced.